SOFTFORMING stefani one

SOFTFORMING Edgebander stefani one

Automatic SOFTFORMING Edgebander stefani one

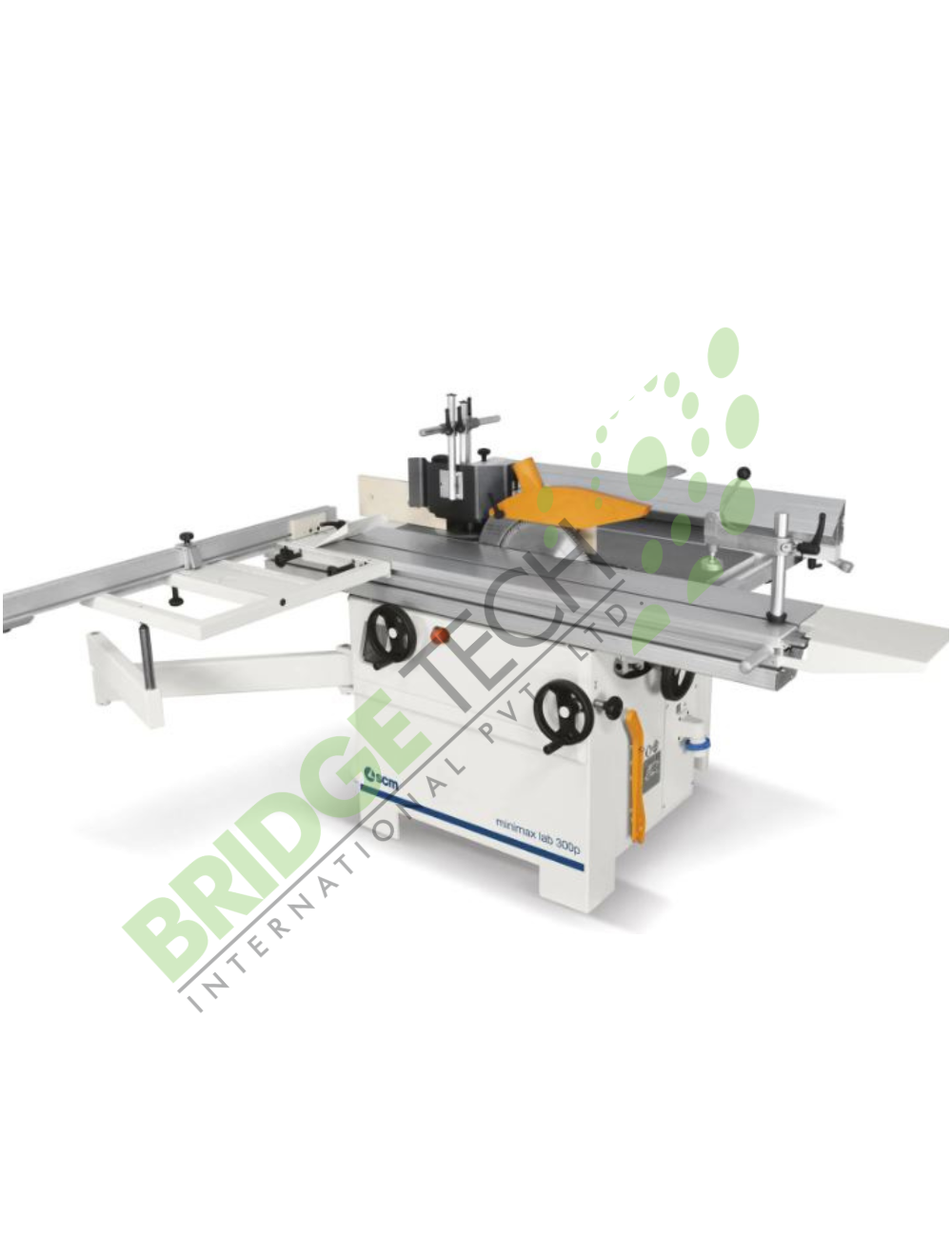

Stefani one is a High End single-sided edgebander designed for large industry and for extra intensive use. Modular lengths of up to 16 meters grants the performance of complete and customized processes for edgebanding of soft-forming components, J-Shape, Doors and Tops with the use of materials for the latest generation finishes. High productivity and low operating costs are guaranteed by the wide range of Heavy Duty working units. Thanks to the specific design they can process any kind of production mixture at the touch of a button.

Description

Advantages

UNQUESTIONABLE MACHINING PRECISION

Perfection of the workpiece quality guaranteed thanks to the new generation of the working units which are 15% more rigid and 50% less invasive on the panel. The units are equipped with 50% smaller and lighter NC positioners, with precision to the hundredth of a millimeter, granting constant machining finish with speeds up to 40 m/min, assisted by hyper precise tool/motor connection.

We always look at the process from the point of view of the panel.

TOP DESIGN, INDUSTRIAL PERFORMANCE

J-shape components, Doors, Postformed Tops, straight or angled drawers, delicate/shaped cabinet doors with or without protective film can be always produced to high production standards, always with the maximum productivity per shift. Thanks to the machine’s load-bearing structure and the non-deformable feed track, fast and constant movements are guaranteed in any condition.

ALWAYS CUSTOMIZABLE FINISH

The choice of the edge/panel join quality can be changed with the utmost flexibility and with the minimum time for retooling. EVA, PUR, EVA / EVA, EVA / PUR, PUR / PUR, SLIM LINE, zero glue line with AirFusion+, glue dosing, automatic glue change cycle, are just some of the possibilities that can be provided on stefani one.

Technical data

| Max feed speed | m/min | 40 |

| Roll material thickness | mm | 0.3 – 3 |

| Strip material thickness (ready-cut/veneer strips) | mm | 0.4 – 1 |

| Max solid wood strip thickness | mm | 25 |

| Panel thickness | mm | 8 – 60 (8-80 opt) |

| Panel dimensions | according to the composition | |

| Max required overall dimensions | m | 15 |

| Pneumatic system | MPa | 6 |

| Gluing technology | EVA, PUR, EVA/EVA, EVA/PUR, PUR/PUR, SLIM LINE | |

| Zero glue line technology | AirFusion+ | |

| Possibility to integrate in a cell | Yes | |

| Machine versions | Left (right on request) | |

| Type of panel introduction | Manual (std) Semiautomatic (opt) Automatic (opt)  |

Reviews

There are no reviews yet.