5 AXIS ULTRA CNC

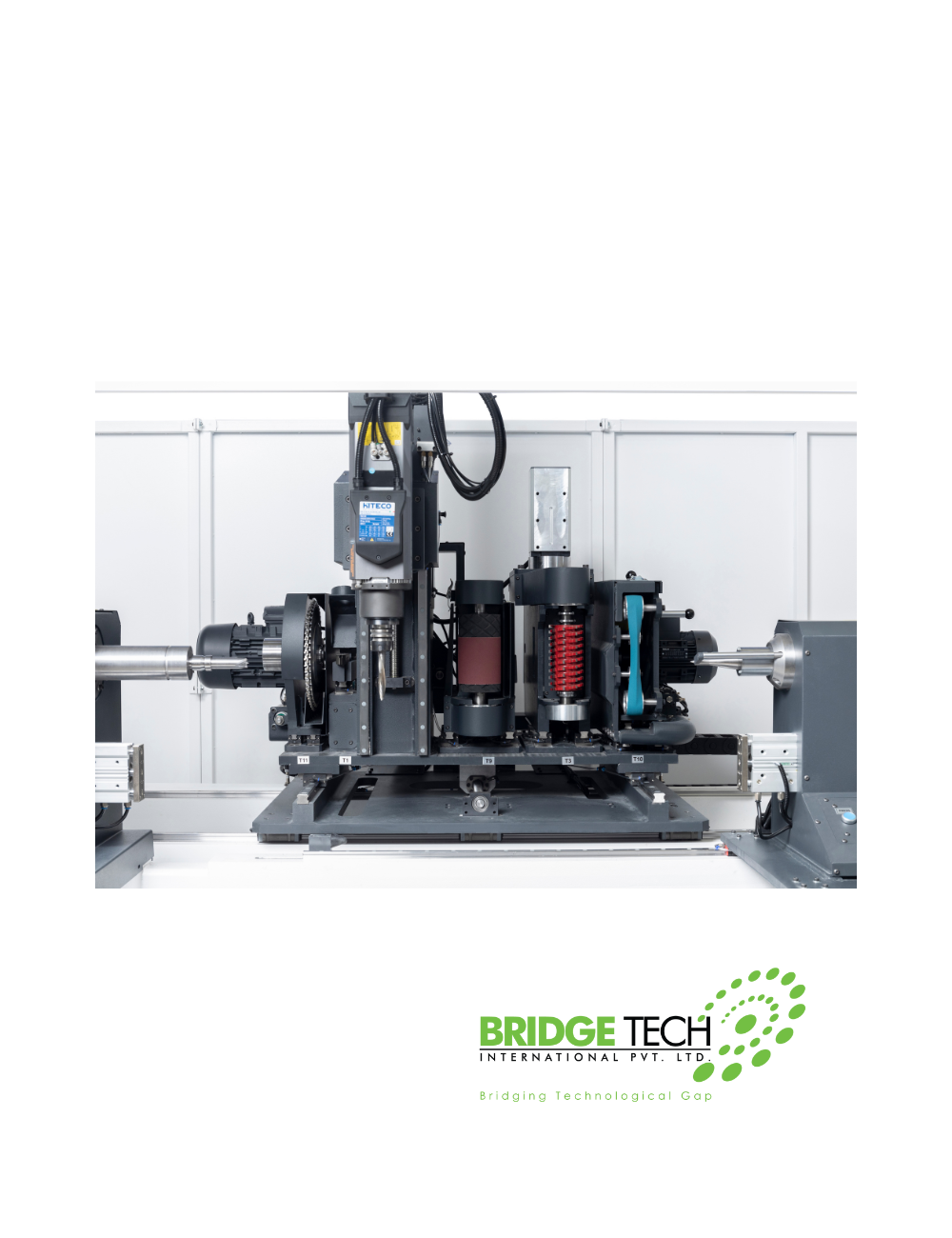

5 AXIS ULTRA CNC WOOD LATHE MACHINE

GENERAL SPECIFICATION

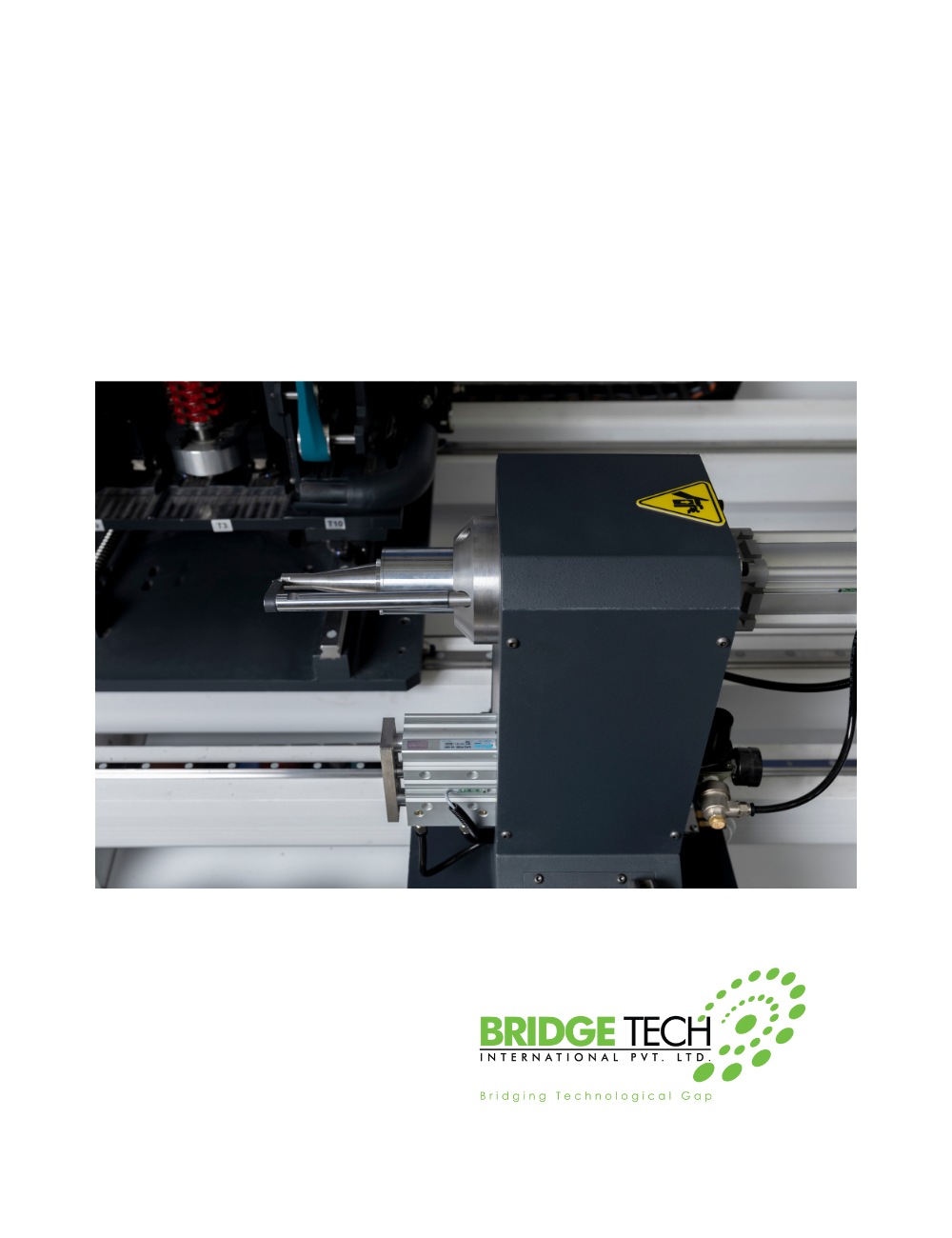

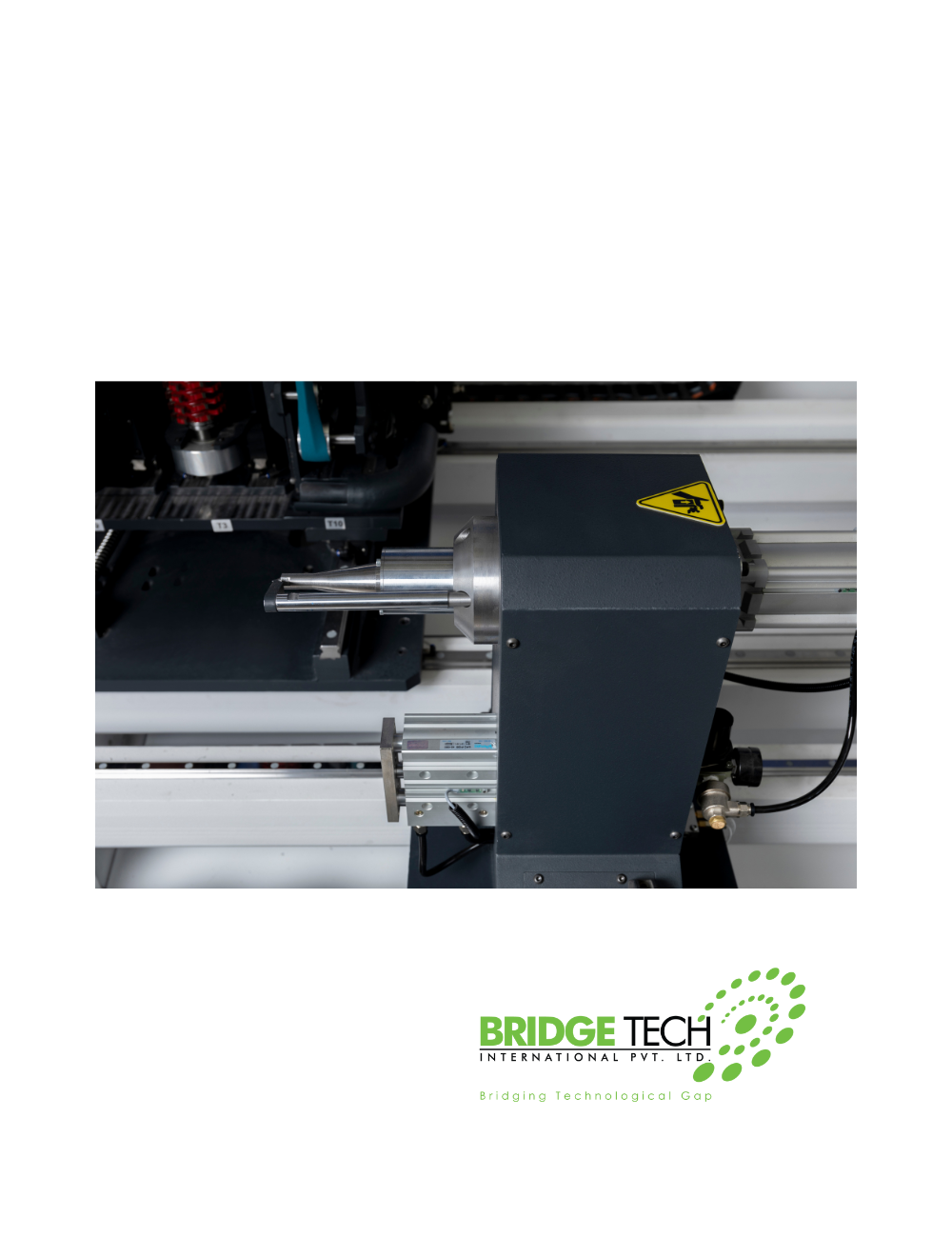

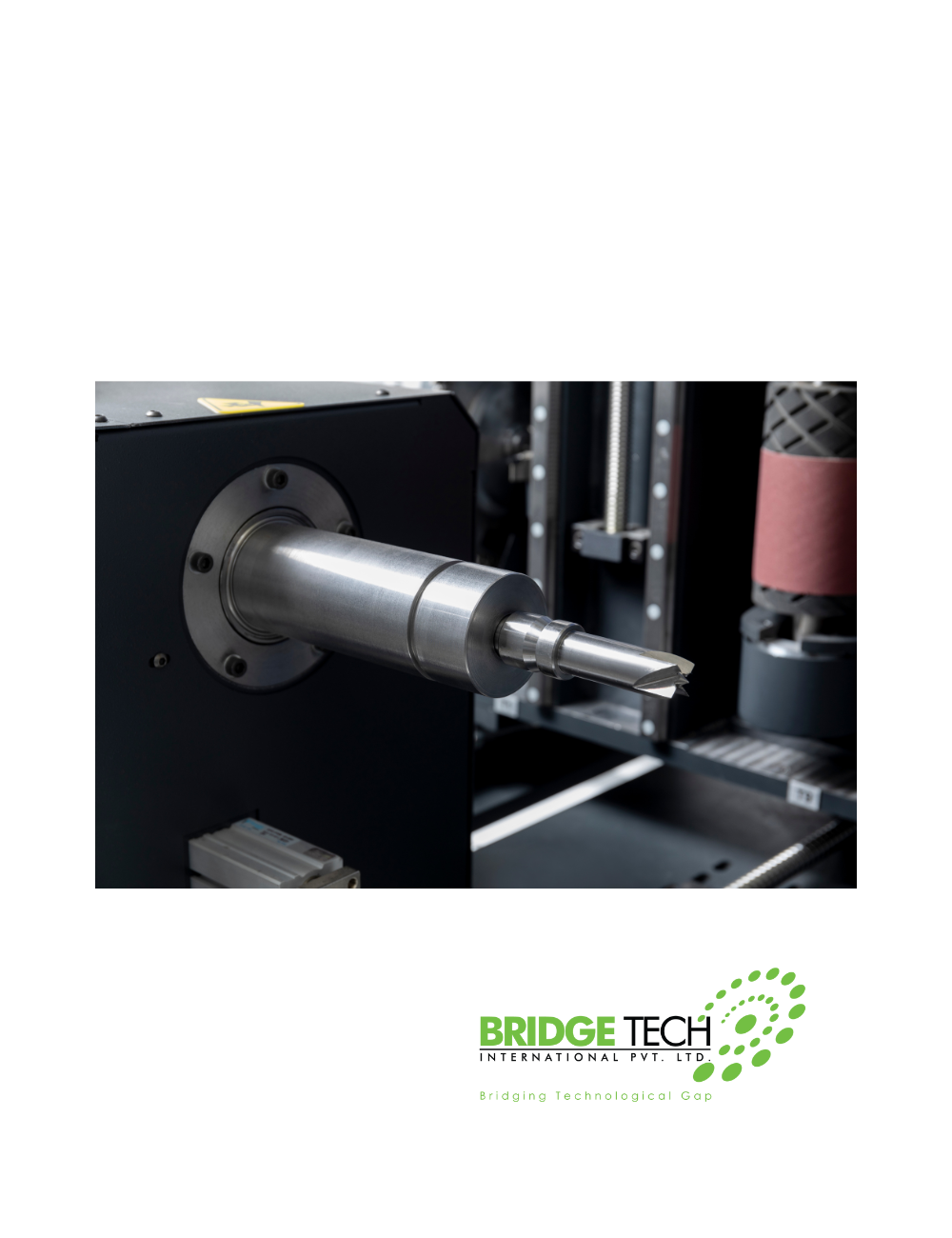

High-resolution Panasonic Japanese servo motors are used in our machine. The axis that

rotates the part has the “Direct Drive” function and can work with a 5 kW servo motor at

4500 rpm. Precision ball screws and nuts are used in all axes. Workpiece length setting can

be adjusted with a single knob. This ensures time savings and long-term linearity of the

tailstocks. The control unit has a remote control function. In addition, with functions such as job

sequencing, detailed reports and display of the three- dimensional state of the workpiece, the

TPA control offers the user great convenience .

Description

Structure Of Chassis

With its reinforced, vibration-free and stable chassis design, it provides accuracy over long

production cycles and remains reliable for your machining needs. It has an impressive frame

design that provides reliable precision in operation

Axis Movements

All axes are driven by servo motors. They allow precise acceleration at high speed. High quality and high

precision rails, carriages and racks are used to prevent the movement of the axes from being affected by

the slightest vibrations.

Central Automatic Lubrication Units

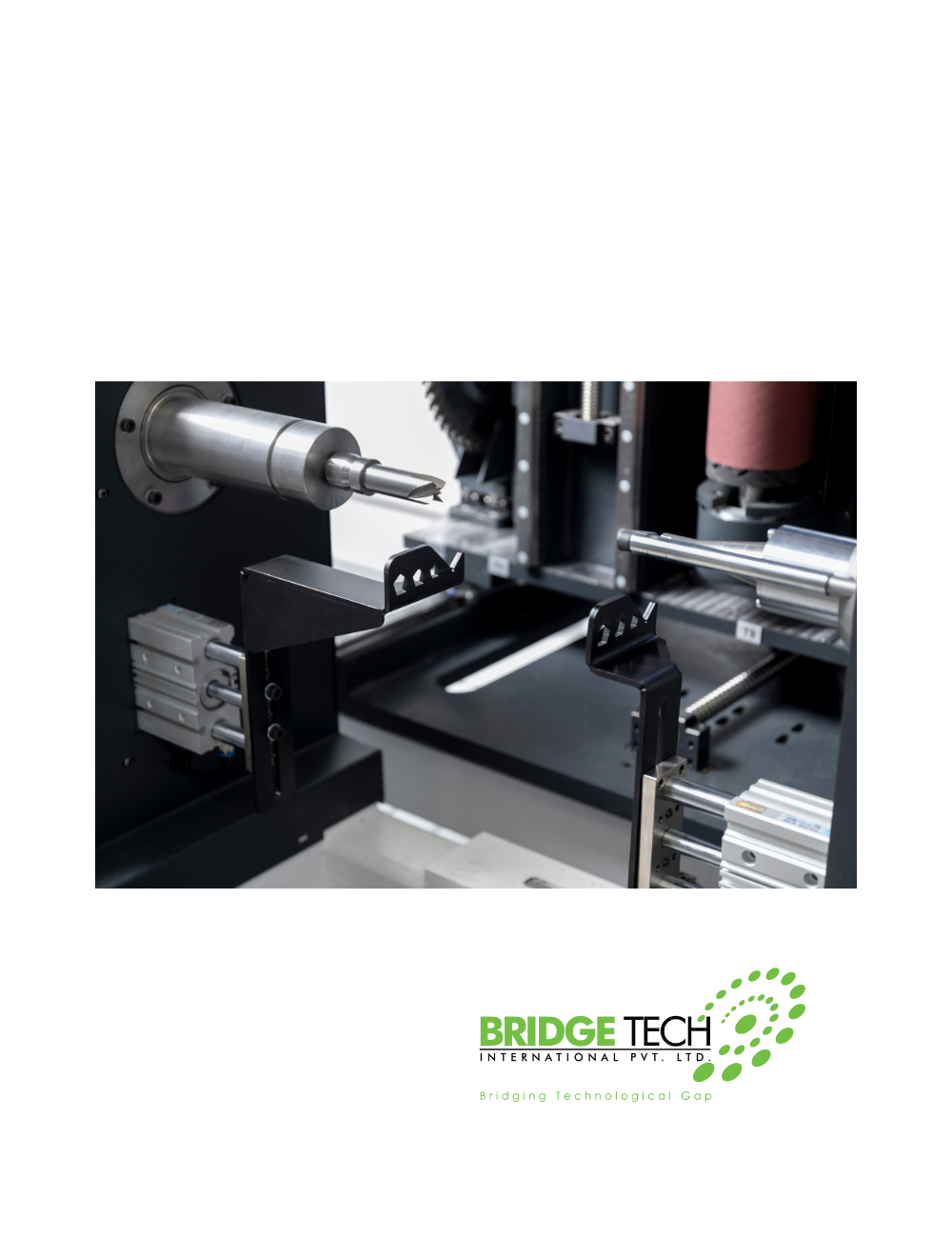

Automatic Tool Measurement Units

Tpa Control Unit (ltalian)

CAD/CAM SOFTWARE / PEGASUS CAD&CAM

Pegasus 5 Axis Plus CAD-CAM Program

(Plus Version Optional)

MAIN COMPONENTS

C Cup Blade for Gouger C Shaper-Debarker Blade C Triangle Blade for Gouger

Automatic Tool Changer

5.5 – 6 kw Hertz spindle motor

Optional Component

Hiteco Spindle ( optional)

oscillated sanding unit

Detail Sanding unit enables

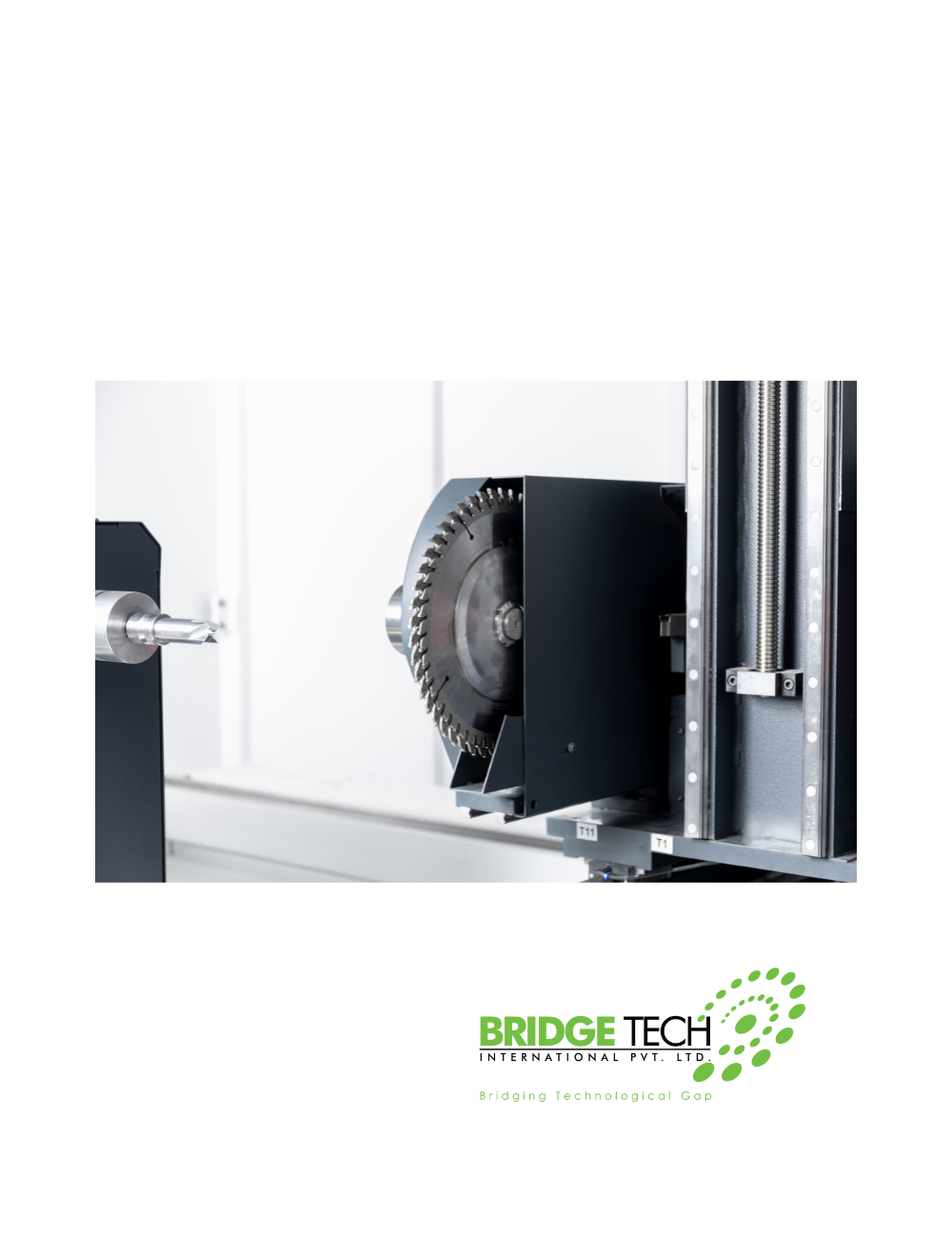

Saw Blade Unit

Aluminum Debarker Blade

ACCESSORIES

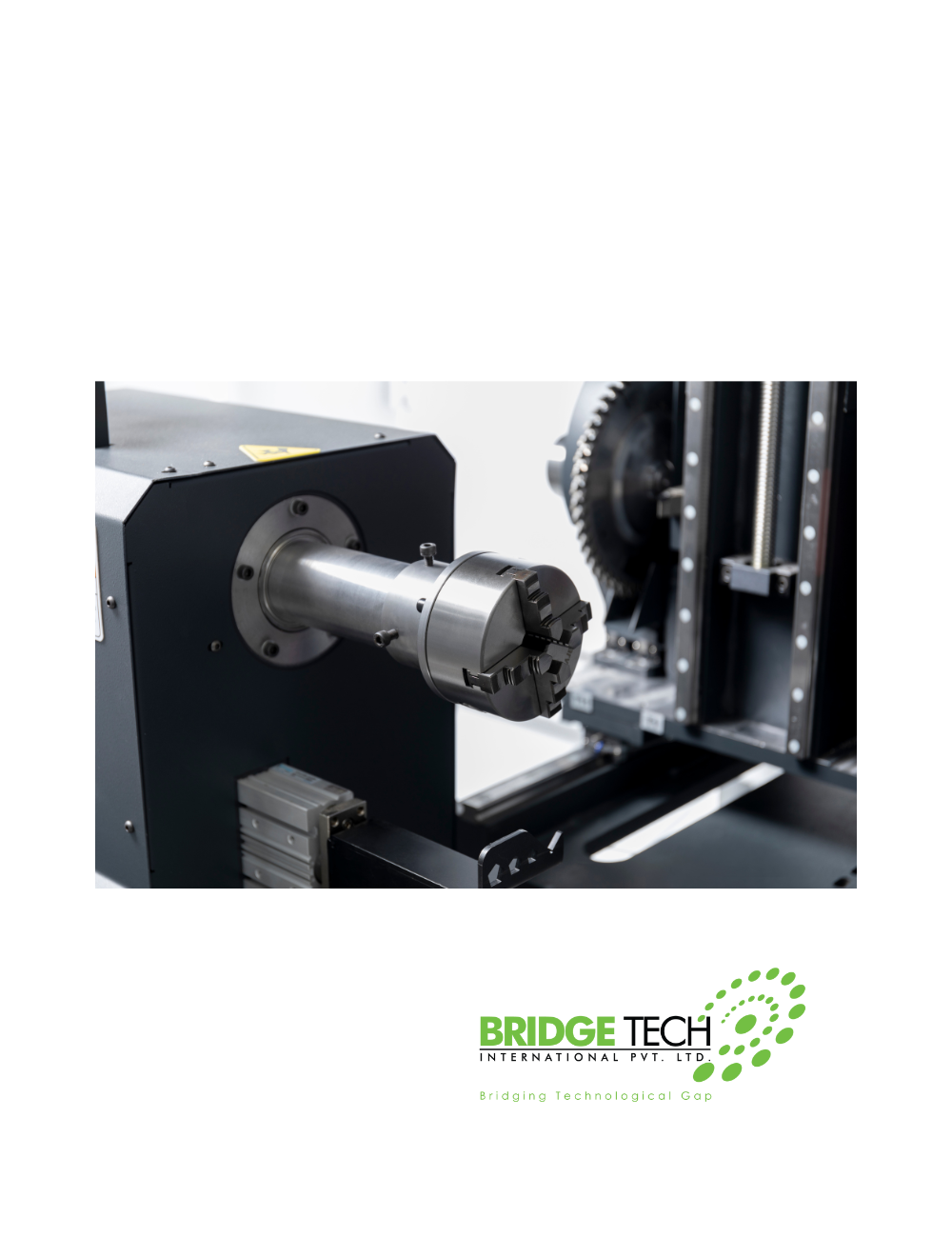

Conveyor Asynchronous Tail Stock Handwheel

OPTIONAL ACCESSORIES

Automatic Loading Unit Aluminum Table Jaw Chuck jaw chuck

Warranty Period

The machine is guaranteed for 1 year from delivery from the manufacturer to the customer. The warranty

covers the cost of spare parts and service, except for the operating errors listed in the user manual.

Installation And Training

Installation and training services should be performed by Nesto personnel or by a NESTO authorized

dealer/service provider. Installation and training services are included in the price. Installations not

Performed by Nesto or a Nesto authorized dealer/service provider will void the machine warranty.

Machine installation and training activities cover a period of 3 days. Training activities include general

machine use and CAD /CAM drawing program training.

For Technical Details and Specification please asked to M/S Bridgetech International .

Reviews

There are no reviews yet.