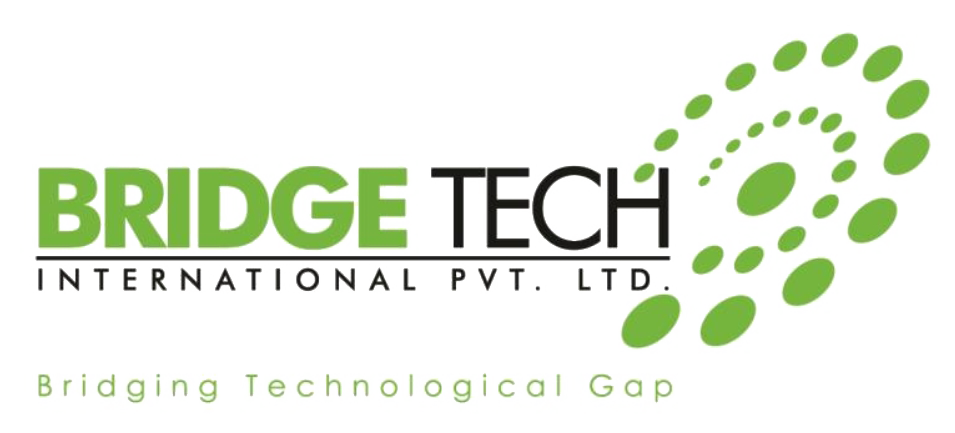

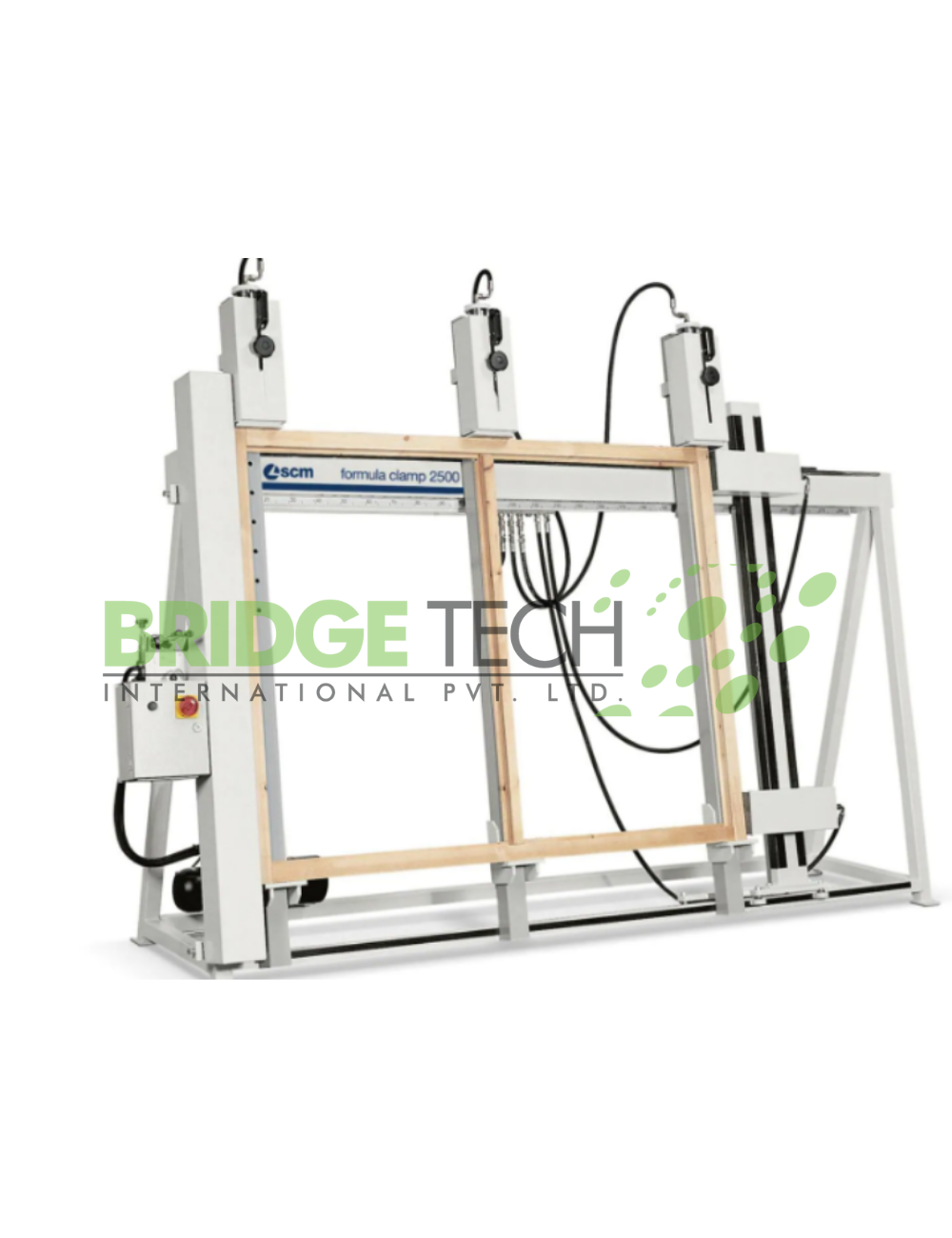

formula ten 400 – ten 400e

formula ten 400 – ten 400e

The automatic tenoning machine which allows very high working rapidity and accuracy.

The tenoning unit is equipped with two vertical and one horizontal pressure cylinders for the work-pieces locking and the machining even of large elements.

Advantages

Accurate positioning

The worktable is fitted with a tiltable fence up to ± 45°.

High efficiency

Carriage movement on ball bushing linear guides and positioning by means of 5-position revolver.

Perfect tenoning operations

Revolver with 4 mechanical stops for the work-piece positioning during tenoning machining, without needing cutting-off operation.

Maximum performances as standard

The formula ten 400e machine version is fitted with spindle moulder unit including an electrospindle with HSK 63B rapid tool change.

Description

Technical data

| formula | ten 400 | ten 400e | |

| Spindle moulder unit | |||

| Max. tool diameter | mm | 360 | 360 |

| Spindle diameter | mm | 40 or 50 | 40 or 50 |

| Tool rotating speed | rpm | 3600 fixed | up to 3600 |

| Tool change system | manual ring | HSK 63B | |

Reviews

There are no reviews yet.